We use machine learning technology to do auto-translation. Click "English" on top navigation bar to check Chinese version.

Manufacturing Optimization for the Electronics Industry: How to Accelerate Product Development and Drive Engineering Efficiency with Instrumental Inc. on Amazon Web Services

Challenges of New Product Development in Electronics Manufacturing

The pressures of miniaturization, functional complexity, customer quality demands, costs and margin, competition, and environmental expectations make the development and production of electronic devices harder than ever before. They have become more complex and so have their supply chains – often spanning multiple countries and continents. Manufacturers must balance these pressures to produce products that are cost-effective, reliable, environmentally sustainable and that can launch on time.

There are two parts to the lifecycle of high-tech electronic products:

Increasing Efficiency in NPI with Data and AI

A

Product design engineers (PDE) experience first-hand the challenges and high costs associated with identifying and resolving issues in NPI, because they are responsible for designing and validating the parts and the assembly process for new high-volume devices. This process typically happens on manufacturing lines, and in factories that are located overseas.

To resolve issues, PDEs must access manufacturing data from the assembly process, but it’s often insufficient to discover and solve problems. This is why they must often fly abroad to factories – often to stand on the line hoping to be in the right place at the right time to catch defects and identify opportunities to improve the overall design or assembly. When issues arise, they physically collect and disassemble units, doing detailed failure analysis to identify the root cause. Sometimes this process involves aggregating vast amounts of test data from multiple sub-assembly suppliers and doing statistical analysis to discover correlations and relationships that could help identify a fix.

Because the primary goal for many PDE teams is to quickly find and fix issues during NPI (so that MP can start on schedule), it becomes very challenging to stay on track with global supply chains, diverse factory locations, and no reliable access to all of the manufacturing data they need to be successful.

In order to recover the billions of dollars in waste, electronics manufacturers will have to think bigger than solving problems one unit at a time in mass production. This means they’ll need to reimagine what forensics and optimization truly means — and when it happens. For the electronics industry, modern manufacturing optimization is about scale and speed – and that takes new tools and technology.

Amazon Web Services Enables Manufacturing Optimization for the Electronics Industry

Amazon Web Services (Amazon Web Services) offers a variety of services and solutions that enhance manufacturing efficiency. They recognize the importance of digital transformation in manufacturing and partners with industry technology leaders like

Instrumental aggregates product data and uses advanced AI and computer vision software to present engineers and operations teams with actionable information that enables them to optimize their product and process.

The team focuses on building features for its customers and relies on Amazon Web Services to run code, manage data, and integrate applications, without managing servers. Amazon Web Services’ Serverless computing services, like

Working with Amazon Web Services also enabled Instrumental to leverage a wide range of services to support manufacturers. With over 3B data points processed, Amazon Web Services is critical for big data analytics, identifying inefficiencies, and improving productivity. And thanks to its

Lastly, Instrumental relies on Amazon Web Services’ AI services, like

Case Study: Lenovo

When working with Lenovo, Instrumental helped accelerate and improve production yield, which led to significant savings. Lenovo’s production managers used real-time paretos and trend dashboards to prioritize daily work. By leveraging Instrumental’s AI, over 200 defect types were automatically discovered, enabling engineers to launch over 58 real-time tests.

“Programs that used Instrumental during development ramped faster than products that did not use it.” – Director of Engineering and NPI, Motorola Mobility

Instrumental on Amazon Web Services

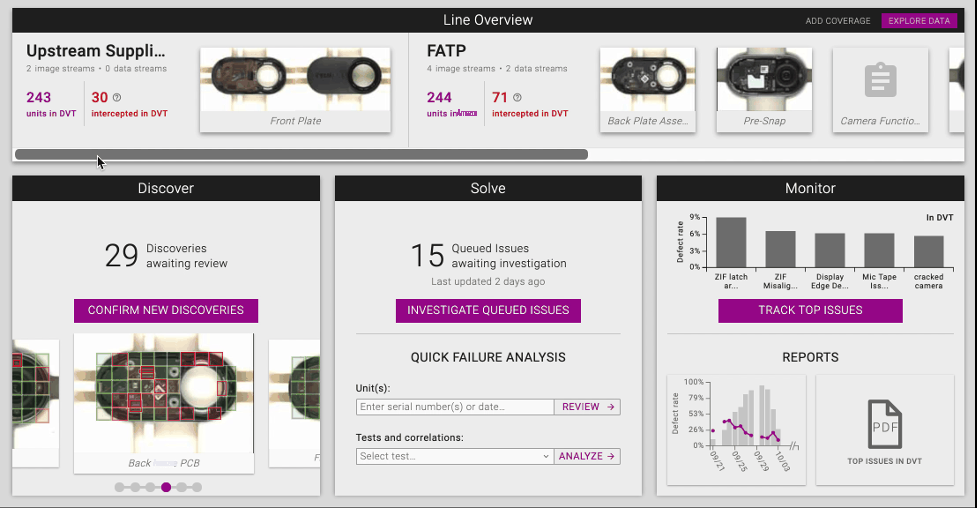

Instrumental delivers proven R.O.I by improving operational efficiencies through AI-powered proactive defect discovery, end-to-end failure analysis tools, and remote real-time build monitoring, all in a simple cloud platform. The application delivers a unified, traceable data record to help identify and investigate issues, act on it faster, and solve previously intractable problems on assembly and manufacturing lines with AI.

Because engineers and operations teams face different challenges throughout the product lifecycle – which are dependent on product complexity, the number of unique Stock Keeping Units (SKUs), and production volume – Instrumental offers two suites of tools. The first is a product development suite focused on failure analysis in NPI, and the second is a production suite focused on oversight and rapid problem-solving in MP.

In product development (NPI), the tool suite focuses on three core functions: discover, solve, and monitor:

- Discover : With proprietary computer vision algorithms, Instrumental’s camera stations can quickly be set up at key nodes of the assembly lines. Using computer vision, anomalies are automatically detected after 30 minutes and with only 30 units. This allows engineers to find and fix functional failures earlier in their build, preventing them from becoming larger problems.

- Solve: Using test data, engineers can leverage Instrumental’s AI to crunch through images and test data to find correlations and suggest potential root causes.

- Monitor: To maintain high yields on their production lines, engineers leverage the camera stations’ computer vision capabilities. In just a few clicks, they can train the stations to differentiate between passing and failing, preventing issues from ever reoccurring.

In mass production (MP), manufacturers aim to maintain stability and continuously improve while reducing costs and driving efficiencies:

- Monitor and maintain: In mass production, manufacturers are constantly looking for ways to reduce costs without sacrificing quality. With unified remote monitoring and proactive alerts, issues are caught earlier before they lead to missed targets. Engineers can view control charts and receive alerts for any test from any source, proactively notifying them of drifts and other Statistical Process Control (SPC) violations. Instrumental also provides out-of-the-box access to Cpk and other KPIs to give vital visibility to potential issues as they happen, ensuring that processes remain stable.

- Continuously improve: Instrumental also helps manufacturers continuously drive higher quality and yield. With real-time insight on the factory floor, operations teams have the time and the right data to investigate and improve operations.

- Mitigate risk and anomalies: Lastly, when a line is down, or for companies experiencing high return rates, Instrumental delivers integrated failure analysis to find the root cause and get back on track fast.

Conclusion

Inefficiencies in manufacturing lead to poor yields and delayed programs and returns which are very costly and can negatively affect brands. Instrumental’s cloud based AI-powered solution built on Amazon Web Services helps engineers access their data from wherever they are, and offers automated anomaly detection and correlations tools.

The implementation of manufacturing optimization techniques outlined in this blog with Instrumental on Amazon Web Services can help reduce defects, improve yield and enhance engineering efficiencies.

The mentioned AWS GenAI Services service names relating to generative AI are only available or previewed in the Global Regions. Amazon Web Services China promotes AWS GenAI Services relating to generative AI solely for China-to-global business purposes and/or advanced technology introduction.