我们使用机器学习技术将英文博客翻译为简体中文。您可以点击导航栏中的“中文(简体)”切换到英文版本。

工业机器人的自适应重编程和云端刀具路径验证

访客博客作者:HAL Robotics Ltd. 首席执行官塞巴斯蒂安·安德劳斯

在

HAL 机器人框架 提供了模块化、可扩展和可重配置的工作流程。这包括与数据源的连接、单元建模、刀具路径生成和验证,一直到机器人代码生成、上传、执行和数据采集以进行分析。

该框架具有很高的可移植性。它可以在桌面、云端、嵌入式系统上运行,甚至内置于 CAD 软件中。HAL Robotics Framework 还不受供应商限制,它支持来自不同制造商的近 1000 台机器人,包括ABB、KUKA、Universal Robots、Yaskawa、Kawasaki和FANUC等。

超定制和可变生产

从汽车零件到冲浪板,再到厨房橱柜和航空航天部件,制造公司必须应对管道中越来越多的产品变化。这通常是因为他们开始自动执行手动完成的任务, 或者 他们计划为客户提供更多的自定义和专业化。“传统” 自动化技术无法适应生产的可变性,这就是自适应重编程发挥作用的地方。

通过使用数据而不是手动编程为机器人生成刀具路径,我们本质上可以处理变化。这些数据可以是几何 CAD 模型、数据库中的文本或任何其他数据格式,前提是数据的使用者能够正确处理数据并从中生成刀具路径。

这种方法通过新的命令和控制范式扩展了工业4.0对设备连接、数据采集和监控的关注。无论是通过真正的量身定制服务还是模块化组装,自动化的灵活性都是保持规模经济的关键。尤其是在我们继续朝着更加以人为本的设计迈进时,即从人类手中移除枯燥、肮脏和危险的工作,降低使用机器人的进入门槛。

流程优化

为了实现自适应机器人重新编程的所有好处,我们仍然需要确保我们运行的过程可行、安全和高效。有两种不同的方法可以处理这个问题。要么手动为所有部件设置安全参数,例如机器人的工作区域、速度和工具选择,要么针对流经管道的每个新零件微调我们的流程。仿真可以验证变体,而无需使用真实的机器人。但是,逐部分测试不同的参数和配置非常耗时,如果手动完成,则违背了自适应编程的目的。

这就是云端完整的机器人编程和仿真堆栈带来红利的地方。通过利用云计算能力来运行高性能的数字孪生实例,我们可以并行测试不同的选项,并就如何处理部件做出明智的自动决策。这些决策可能范围广泛,比如哪个机器人单元可以处理零件,一直到刀具路径生成策略的细微之处。例如,在装有大型和小型砂光机的机器人单元中,我们可以确定对于特定零件,尽可能使用较大的砂光机并仅出于细节考虑而改用较小的砂光机是否更有效,或者更换工具的成本是否超过了使用较大刀具覆盖更大区域的好处。

自动设计验证 PoC

2022 年 9 月,HAL Robotics 参与了

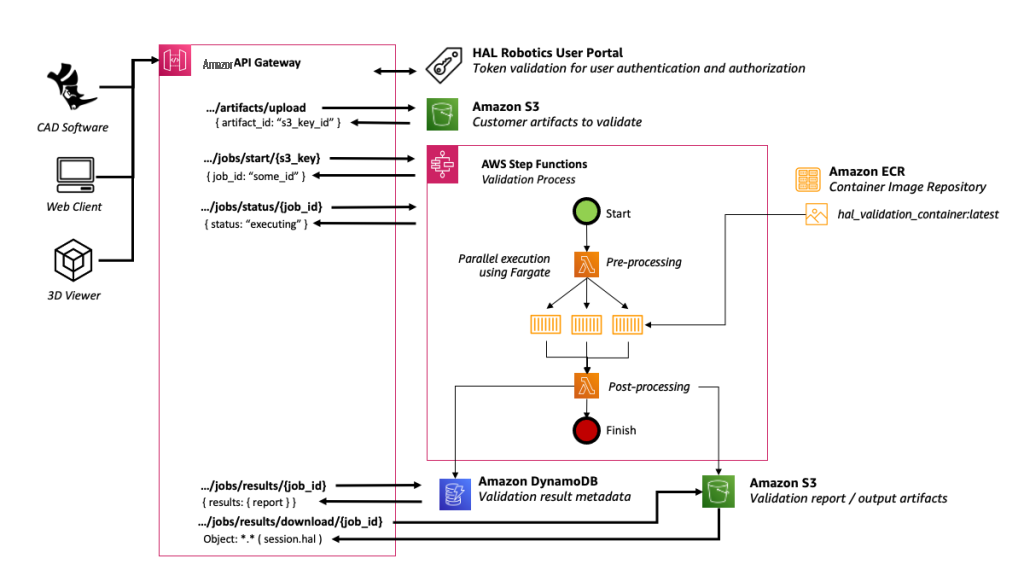

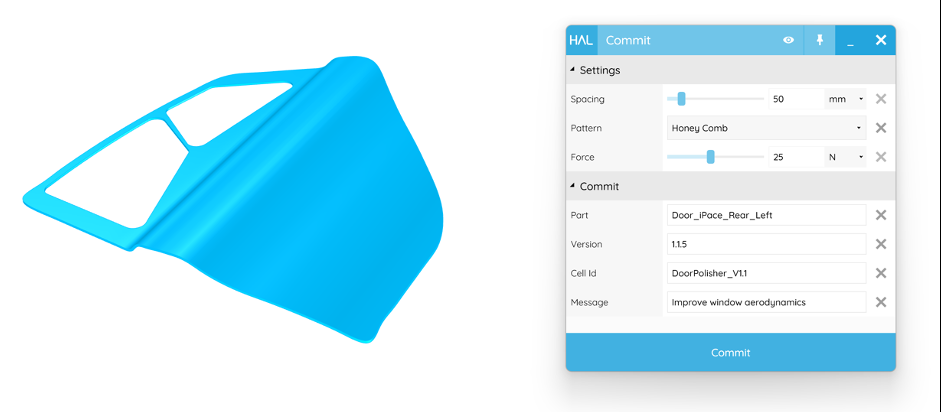

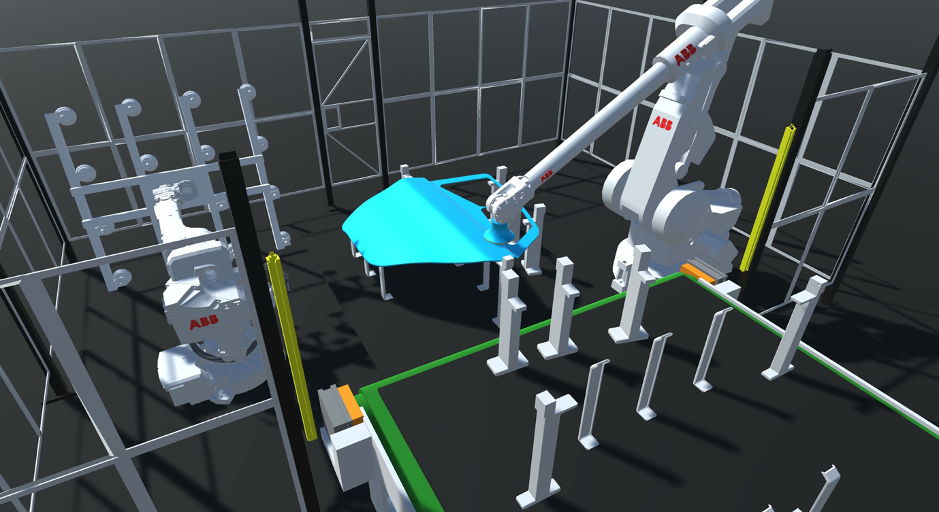

基于 亚马逊云科技 服务的解决方案(上图)在设计部件和验证其在云中的高效可生产性之间创建了一个闭环。通过简化的车门抛光工艺可以证明这一点。工作流程从设计师更改他们想要在 CAD 软件中生产的零件开始。一旦他们对零件的这个版本感到满意,他们就会将这些更改连同生产零件所需的一组参数一起提交到变更跟踪系统中。在演示中,参数包括抛光力范围、图案选项以及可以处理零件的机器人单元。在现实场景中,设计数据和生产参数可能来自两个不同的人,也可以直接来自对生产过程知之甚少或一无所知的客户。

将设计和参数分别推送到

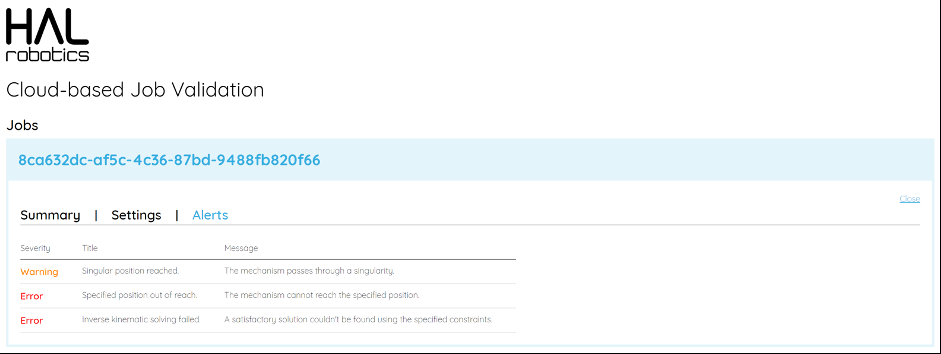

该容器映像为特定机器人单元生成刀具路径并求解刀具路径以确保可行性,识别任何潜在问题并计算出许多指标,例如持续时间或能源使用量,这些指标可用于对不同的有效选项进行评分。然后,将这些指标与使用的参数、任何错误以及过程的数字双胞胎仿真一起推送到 DynamoDB。

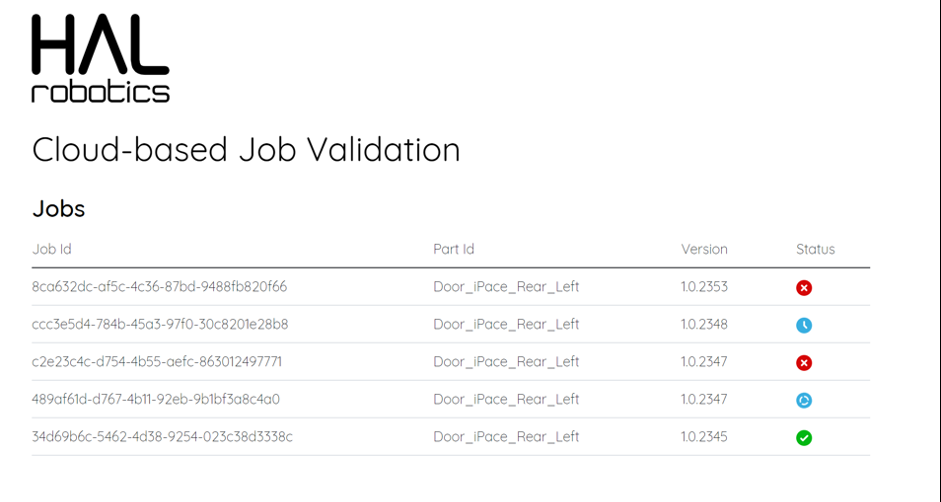

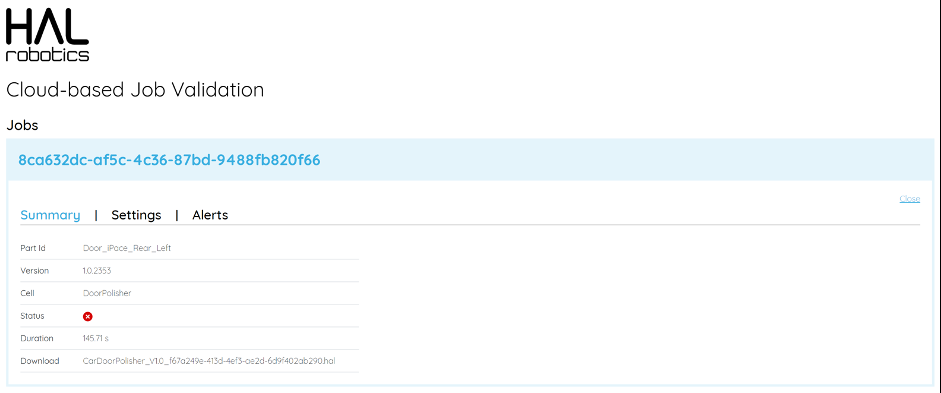

用户可以登录到门户网站查看他们的验证运行情况、深入研究指标并下载模拟。然后可以在计算机上的交互式 3D 查看器中查看模拟。

这种工作流程使设计人员能够在他们选择的软件中进行设计更改——从确保可以生成新设计到优化处理。他们无需触摸一行机器人代码、手动更改参数或等待任何仿真运行即可完成此操作。

结论

此处提出的解决方案是进行产品设计更改和检查这些更改对生产过程的影响的强大工具。与 HAL Robotics 堆栈的其余部分结合使用时,它可以进一步提高生产力,在其中您可以创建从设计到高效变量生产的端到端工作流程。例如,一家 3D 打印公司可以允许用户使用一些用户可访问的参数将其模型上传到网站,然后触发上述验证工作流程,并将最佳结果推送到 HMI,操作员只需按下播放键即可。

更进一步,该解决方案可以在生产循环中运行。在 HAL Robotics 中,有许多流程无法事先知道进入细胞的部件。在这些情况下,我们使用三维扫描仪等传感器来捕获有关零件的信息,然后使用边缘计算使用这些数据生成刀具路径。尽管这些流程始终正常运行且安全,但为实现这种灵活性而牺牲了少量效率。借助云和并行化的强大功能,您可以在相同的时间内生成和验证 10 或 100 条不同的刀具路径。这种工作流程在增量生产线中变得特别普遍,这些生产线将传感器和多个过程结合在一起,以修复回路中的缺陷,或者通过将流程相互分层来制造极其复杂的部件。示例包括增材制造和交替刀路加工。

HAL 机器人框架多年来一直支持自适应自动化。现在,通过展示其在弹性云服务中的可移植性,我们可以解锁所需的可扩展工作流程,即使是最苛刻的制造系统也能提高灵活性。

要下载 HAL Robotics 框架并了解有关此解决方案的更多信息,请访问

*前述特定亚马逊云科技生成式人工智能相关的服务仅在亚马逊云科技海外区域可用,亚马逊云科技中国仅为帮助您发展海外业务和/或了解行业前沿技术选择推荐该服务。